Technology has produced a bonanza of oil and gas. But many want assurances that water resources are not being harmed.

Whatever you may think about oil and gas drilling, acknowledge this much: The technology is jaw-dropping. A decade ago, library shelves were sagging with books foretelling declined production of oil and natural gas. Guess what? In July 2013, the International Energy Agency announced that the United States will become the world’s leading producer of natural gas in 2015 and the world’s leading producer of oil in 2017.

The technology driving increased production isn’t altogether new. Hydraulic fracturing was first used in Colorado in 1948. The application of water, sand and chemicals at high pressures to stimulate production is called by the industry and regulators a “frac.” To journalists, that spelling looks unkempt, so the news outlets call it a “frack.” To opponents, it’s a four-letter word no matter how you spell it. What’s different between those original fracks and those currently done an average of five times every day in Colorado is like the chasm between the first Apple computers and MacBooks today: the new versions are immensely more powerful—and more precise. Instead of pumping fluids by the thousands of gallons, as the first fracturing jobs did, today companies commonly use more than 5 million gallons of water to “shoot” deep rock layers and fracture them. Tiny fissures smaller than a follicle of hair are formed and propped open by sand particles and other “proppants,” allowing the oil and gas to escape out of the rock and into well casings. Fracturing chemicals, which constitute less than 1 percent of hydraulic fracturing fluid’s total volume, are used to improve effectiveness. Many are ordinary, benign household or industrial substances, but some are known carcinogens and other toxins, raising concern about potential impacts to water quality.

The industry has proclaimed fracturing fluids safe for their intended use—thousands of feet underground—and Gov. John Hickenlooper in 2011 even sipped on a glass of Halliburton’s new “green” frack fluid, called CleanStim, as if it were a scotch and water. Not everybody’s buying such assurances. If it’s so safe, say opponents, why have companies for so long resisted disclosing the contents? The industry says it’s about maintaining that competitive edge; who can provide the most effective frack? In Colorado, but not all states, both chemicals and their relative proportions as a percentage of total fluids injected during fracking are a matter of public record since 2012. Recipes for specific ingredients, however, remain private under laws that protect intellectual property.

Horizontal drilling has also enabled drillers to more efficiently extract the hydrocarbon residue of organic matter in ancient sands, muds and other sedimentary rock. It’s down, down you go, to 3,000, 5,000 and even 10,000 feet, and then slowly hook to the left or right into the unconventional deposits, so-called because they are so much more tightly compressed and cemented, the spaces between particles not even half as large as those of previous, or more conventional formations containing “reservoirs” of oil and gas. Another key technological gain is 3-D seismic imaging, which allows exploration teams to better visualize oil and natural gas prospects, place wells more effectively, and reduce the number of dry holes.

These technologies, backed by powerful computers, converged with increased experience and the incentive of higher prices to create something of a perfect storm for exploration in about 2003, and today supplies are bountiful. It’s been widely heralded as a game-changer. Manufacturers are returning, enabled by cheap chemical feedstock provided as part of natural gas production. U.S. per-capita emissions of carbon dioxide have actually decreased in recent years as natural gas displaces coal for electrical production. Boosterish talk of national energy independence abounds. Some companies even want to export natural gas abroad.

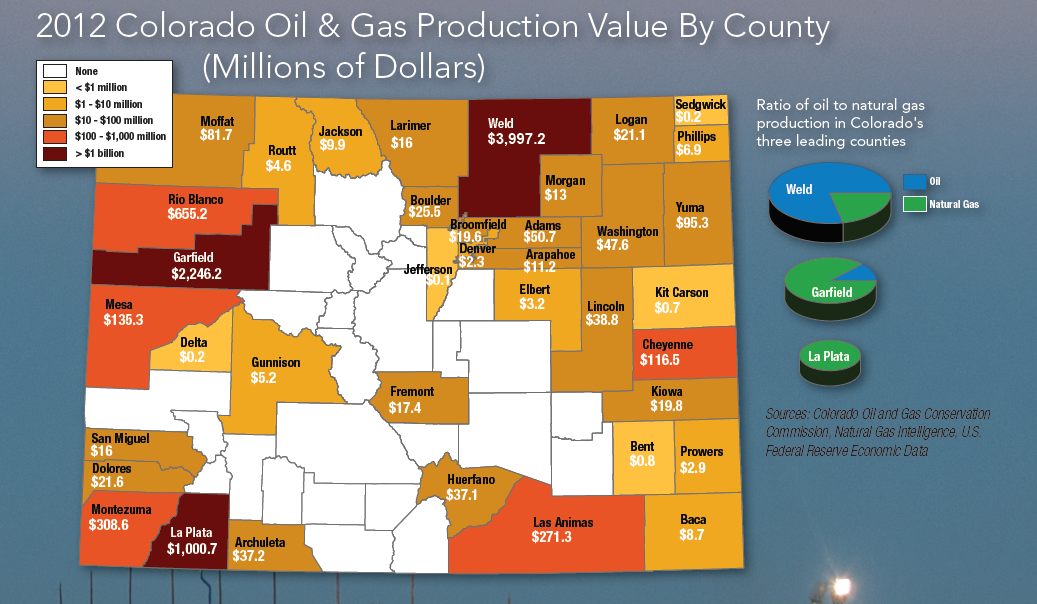

In Colorado, lower natural gas prices have meant lower heating bills: Average household energy costs here are 23 percent less than the national average, according to the U.S. Energy Information Administration. The surging oil and gas sector also delivers paychecks for 30,000 people in the state and contributes handsomely to tax coffers. Colorado’s severance tax in 2012 yielded $163 million, half of which was distributed directly to local governments. A portion is also allocated to state water programs and loan funds via the Colorado Water Conservation Board. During the 2012 fiscal year, the Colorado Foundation for Water Education received 40 percent of its revenue indirectly from state severance taxes.

For billionaire energy entrepreneur T. Boone Pickens, all this is good. “I want to get rid of ethanol. I want to get rid of OPEC. I want to get natural gas in transportation,” he said in August 2013 at the American Renewable Energy Days conference in Aspen. “I don’t think I am talking to a group of people who are all that keen on drilling anything,” he added, but warned: “You’re going to have to deal with natural gas for 100 years. It’s going to be around that long. We have a lot of natural gas in this country.”

That, in the view of skeptics, is exactly the point. It’s an issue of scale—and costs. What do we really know about the impacts to water? That’s not to mention the round-the-clock clanging, incessant lights, rumbling trucks and pungent odors associated with oil and gas development, all of this sometimes literally in suburban backyards, in fields next to schools, and in pastures where cattle graze. If Colorado is to be such a major source for oil and gas, shouldn’t we get it right—and now, not later?

Trési Houpt was elected as a commissioner in Garfield County in 2002 as drilling rigs sprouted conspicuously in the Piceance Basin. The basin arcs broadly from Carbondale through the Colorado River towns of Silt, Rifle and Battlement Mesa and toward one of Colorado’s oldest oil towns, Rangely. She says drilling companies weren’t communicating well with landowners then. That has improved. So have regulations intended to protect the environment and public health. But more, in her view, needs to be done.

“It could have happened to anybody,” she says of a spill of chemicals including the carcinogen benzene, a component of crude oil, found this year along Parachute Creek, a tributary to the Colorado River. “I think the contamination of Parachute Creek is just one more example of why we need to be extremely thoughtful about how we develop near waterways and whether we actually should.”

Trési Houpt, former Garfield County commissioner. Photo By: Todd Patrick

Houpt, who also served on the Colorado Oil and Gas Conservation Commission from 2007 to 2011, is among many Coloradans who believe the implications of the oil and gas technology revolution have not been fully vetted. “Why not progress thoughtfully as we utilize this resource and, at the same time, work on the technologies that potentially could make it safer to drill in more populated or sensitive areas across the country?” she asks.

That is essentially the point Longmont is making, now followed by other cities along the Front Range, where citizen-based initiatives are seeking to put moratoriums on the use of hydraulic fracturing—and by extension, drilling altogether—within municipalities. “Stop the fracking,” shouted one protester in May 2013 as Patty Limerick, noted historian at the University of Colorado Boulder, attempted to interview Gov. Hickenlooper at a forum in Boulder. Working to keep the session productive for the other 450 people in attendance, Limerick ordered her out of the room, and soon another heckler was similarly dispatched. But such extremes only frame the edges of what has become a difficult conversation.

The Rise of Natural Gas

Drilling is hardly new in Colorado. In 1862, Colorado had a commercial oil well, thought to be second in the nation, near Florence, a few miles from Cañon City. Oil seeps led to development of a field north of Boulder in 1901, followed in 1920 by other fields near Fort Collins and Rangely. After World War II, the latter became one of the nation’s preeminent fields.

This post-war boom led to the creation of the Colorado Oil and Gas Conservation Commission (COGCC) in 1951. The agency initially set out to create order in the oil fields, to govern spacing in order to create more efficient extraction. The original mission of “preventing waste of the state’s oil and gas natural resources” has since expanded, most significantly in recent years, to include broader environmental protections, the mission statement amended to: “fostering the responsible development of Colorado’s oil and gas natural resources.” Asked about the COGCC’s role in promoting development today, the agency’s director Matt Lepore replied: “We are not a cheerleader for the industry. We are not a marketing arm. We do not set quotas for them.” Rather, the agency oversees well permitting, investigates complaints, collects oil and gas production and water quality data, and enforces federal and state regulations.

These top-producing areas account for the majority of state production. Oil and gas obtained elsewhere nudge state totals up only slightly. Source: Colorado Oil and Gas Conservation Commission

As for natural gas, it was a nuisance at first, produced in the pursuit of oil and flared, to avoid explosion, until pipelines and other infrastructure were installed after World War II. It is often found with coal deposits, and hence the development, still continuing today, in the Raton Basin near Trinidad and the San Juan Basin around Ignacio, both in Colorado’s southern tier.

Since the late 1990s, the Piceance Basin has become a major natural gas-producing area. Pastoral and once-remote settings quickly became a patchwork of industrial zones. From the air, the well pads look like giant subdivisions of cul-de-sacs.

In recent years, industry attention has shifted to the Denver-Julesberg (DJ) Basin. Within that basin lies the highly productive Wattenberg Field, a lump of oil- and gas-bearing sands, shales and silts covering 2,500 square miles between Denver’s outskirts and Wyoming, Longmont and Keenesburg. The seminal or “discovery” well, Grenemeyer #1, located three miles northwest of Brighton, was started on March 6, 1970, and still produces today. Now, the Wattenberg has 22,000 active wells amid fields of wheat, alfalfa and other crops—and increasingly, suburban housing and exurban horse pastures. Their collective production is phenomenal: 120,000 barrels of oil per day during February 2013, or about three-quarters of Colorado oil production. Plus, there was more than 850 million cubic feet of gas per day, roughly enough to supply the gas used to heat eight million homes.

Matt Lepore, Colorado Oil and Gas Conservation Commission director. Photo By: Matthew Staver

Amassing the Wattenberg, Piceance and all other fields, oil production in Colorado hit 49 million barrels in 2012, still short of the record of 58.5 million set in 1957 but with growth trends in recent years as steep as the face of Longs Peak. Production of natural gas as represented on bar charts for decades looked like a profile of the Great Plains, almost imperceptibly sloping upward. Now, the industry is in more rugged territory, the annual growth heady stuff.

Water Quality at Risk?

Over the years, concerns have grown that drilling could contaminate local water supplies. The proximity of the Wattenberg Field to residential areas has served to amplify citizen outcry. Many allege that Colorado laws governing drilling are too lax, that the protection of vital water supplies is disregarded in the frenzy to tap the resource. The focus of the attention has been on fracking.

It’s true there have been spills and other evidence of mistakes, all of them cause for concern. But with 51,000 active wells in Colorado, most of them fracked, the chemicals used in the process have never been shown to migrate underground to drinking water supplies as many have feared. That’s not to say it couldn’t happen. It’s just unlikely.

Aquifers tapped for drinking water are typically found within 1,000 feet of the surface. Oil and gas drillers plunge concentric circles of steel pipe through these shallower layers of rock containing potable water, encase the pipes in layers of concrete, then drill much, much deeper through impermeable layers of what are called cap rocks. These impermeable layers are what have kept the oil and gas underground over eons. In the layers 3,000 to 10,000 feet below ground are the hydrocarbons—and also more water. This deeper water is usually salty, leftover from ancient oceans and seas, and high in dissolved minerals, making it unfit for human consumption.

Limiting the discussion to what is happening underground, potable groundwater supplies can theoretically be harmed by drilling and hydraulically fracturing a well in just two ways: 1) if the steel casing or concrete lining the well bore fails, or 2) if the fractures themselves create pathways extending thousands of feet upward. As regards the latter possibility, energy companies have a vested economic interest in measuring and controlling the length of fractures, in order to reduce the quantity of frack fluids required and protect their ability to drill additional, nearby wells without risking uncontrolled interactions. Microseismic technology enables them to “read” the measurements underground, and the COGCC reports fractures remaining in the “formation of interest” and rarely extending beyond several hundred feet. Even those fractures that reach 1,500 feet typically extend more horizontally than vertically, and remain thousands of feet below groundwater sources.

Although standards are in place to monitor the integrity of well casings, which must extend below potable groundwater supplies, the technique isn’t perfect. Of the 38,000 wells drilled in Colorado since 1990, there have been 15 cases—and possibly a 16th yet unresolved case—where well-bore failures led to groundwater contamination by methane, the primary component in natural gas. Most of these failures occurred prior to 2008, when state rules were changed to require steel casing and concrete extend 50 feet below the deepest aquifer being used for drinking water.

In 2004, for example, a well-bore failure occurred near Silt, west of Glenwood Springs, resulting in methane bubbling from West Divide Creek. The operator, Encana, was fined $371,000. That same investigation in 2004, however, cleared oil and gas activities in the case of methane detected in a private water well along West Divide Creek. The methane there, said state inspectors, came from naturally occurring, near-surface, “biogenic” sources—as opposed to the deep “thermogenic” methane targeted by energy companies. Isotopic testing allows chemists to make the distinction. Although considered harmless if swallowed in water, methane quickly outgases, releasing into the air where it can become explosive.

While methane contamination has occurred, no evidence exists to show fracking chemicals migrating to reach groundwater used for drinking. Not just in Colorado, but nationwide, in fact, there has yet to be any conclusive proof of such contamination occurring. In 2011, the U.S. Environmental Protection Agency released a draft report saying groundwater at Pavillion, Wyoming, was fouled by 13 different chemicals used in fracking fluids, chemicals the agency concluded were introduced during the injection stage of hydraulic fracturing. The agency’s conclusions about how the chemicals came to be in the water samples taken, however, are hotly disputed. The EPA has since stepped aside to let Wyoming state officials further investigate. Some see the move as a sign the EPA recognizes its science was critically flawed, though the EPA continues to stand by its data. The state-led study will be funded, in part, by a $1.5 million grant from the oil field’s operator, Encana.

Chemical Disclosure

What worries some is not what we know. Rather, it’s what we don’t know. A major sticking point has been the lack of transparency about content and quantities of fracturing fluids. How can regulatory agencies monitor for chemical compounds they don’t know to be looking for?

The Energy Policy Act passed by Congress in 2005 excluded fracking from disclosures required by the Safe Drinking Water Act—under which the EPA regulates the injection of fluids underground. In halting steps, states have instituted their own requirements. The nonprofit Groundwater Protection Council in 2011 set up a national Web-based system for voluntary disclosure called FracFocus.

In Colorado, the public disclosure of ingredients used in fracturing fluid was first required upon demand of public officials and healthcare providers. In 2012, Colorado made disclosure via FracFocus a mandatory requirement. All chemicals used since then must be disclosed as a percentage of the total mass of the fluid, but companies remain exempt from reporting their proprietary “recipes.” At the time it passed, Colorado’s disclosure rule was the strictest in the nation, says Lepore. “The Environmental Defense Fund and industry came together and supported the rule. It was a big moment, a rare moment,” he says. Since then, Pennsylvania, Ohio and Tennessee have mod-eled their disclosure rules after those here.

Mark Williams, of the University of Colorado, believes the industry hurt its own cause by being secretive, which allowed worst-case fears to flourish. He sees little risk from fracking, but says the public worries are easily understood. “The potential of contamination by fracking fluids is really, really low—but not zero,” says Williams, a hydrologist who is co-leading a $12 million program funded by the National Science Foundation to explore fracking and other issues involving oil and gas extraction.

But how do we know the risk is low? Some argue that we don’t—unless we have baseline data that records water quality before drilling occurs and then again afterward. Although such data exists for certain regions—in the San Juan Basin, for example, the Colorado Oil and Gas Association reports more than 2,000 samples have been recorded since 2000 with no evidence of impacts to groundwater wells adjacent to drilling activities— it isn’t a complete picture. Colorado began requiring monitoring statewide in May 2013.

“It’s absolutely essential. We need to know what the conditions are in terms of water quality, before oil and gas is extracted, to know if there is a perturbation, or a problem, of contamination,” says Williams. What must be understood, he adds, is that the potential for contamination varies widely as a function of the hydrogeology. “Just because there has been some contamination of a rock formation elsewhere in the United States doesn’t mean that you have an increased likelihood of contamination where you are. It depends upon the hydrogeology of your area.”

To help resolve the uncertainties, Congress in 2010 ordered the Environmental Protection Agency to undertake a major transparent, peer-reviewed study of the potential impacts of hydraulic fracturing on drinking water resources. The draft study is scheduled for public review in 2014.

What Goes Down Must Come Up

Of greater concern than fracking to Williams are the above-ground handling of fluids and the deepwell injection of waste. Millions of gallons of water are forced down wells in fracking operations, and much of that water—along with frack chemicals— returns to the surface. Called flowback water, it must be collected, transported and disposed of.

So must produced, or formation water, which is water pre-existing in the hydrocarbon-containing formations that must be removed to bring up the oil and gas. In the case of coalbed methane wells, which are shallower than other oil and gas wells, the quality of the water is typically high and, in some cases, can be released into streams with little or no cleanup, subject to state water quality standards. Produced water from deeper sandstone formations is more challenging because it is commonly, to use a non-scientific term, nasty—full of salt and dissolved solids. But sometimes it can be of reasonably high quality and could even be a resource for the future.

Spills and leaks of hydrocarbons and waste fluids, both from storage pits and tanks as well as pipelines and trucks during transport, pose a far greater concern than the actual fracturing process itself, say regulators. About 500 spills occur per year on average in Colorado, according to the COGCC. One such accident occurred in February 2013 when a mechanical failure resulted in 80,000 gallons of frack fluid gushing from a well north of Windsor. In a negotiated settlement with COGCC, the operator agreed to pay $35,000, which was seen by some as a mere hand slap but was four times the maximum fine currently allowed by law. A more extensive fine could have been levied had “extensive environmental damage” been proven, but Lepore said no impacts occurred off the well pad or to groundwater. Soils on the well pad were quickly scraped and disposed of. The relative containment of the spill made a difference in the concern, the response and the potential penalties, says Lepore.

llustration by Charles Chamberlin. Sources: Colorado Oil and Gas Conservation Commission, Colorado Oil and Gas Association, Exxon Mobil, New York Times

Gaining more attention was a leak discovered along a pipeline in Garfield County, which has led to benzene contamination in Parachute Creek. The company responsible for the pipeline made the discovery and notified state regulators, but not before more than 10,000 gallons of hydrocarbons had escaped. Some saw this as a wake-up call that buried pipelines across the state, subject to corrosion, pose a looming hazard for environmental integrity. Others saw it as evidence the state is too thinly staffed.

Colorado currently has 19 inspectors charged with monitoring initial drilling and ongoing operation of the state’s 51,000 operating wells. Last winter, the Colorado General Assembly authorized hiring additional inspectors, to a total of 27, which could help the COGCC better enforce its safety regulations. “The regulations are actually quite good,” says Williams, “but regulation is not compliance.”

In September 2013, risks to water quality were again highlighted when flooding waters in the South Platte River Basin toppled tanks and in other ways resulted in what state officials reported were 12 notable releases of oil. Although 1,300 wells were shut down, the releases are expected to cause state officials to review regulations for drilling in floodplains.

Improving Safety Measures

One strategy to reduce spills and improve safety measures is to instill a culture of best practices. The Colorado Oil and Gas Association (COGA), an industry trade group, has arranged speakers at its annual conventions to make the case for stepped-up acceptance of environmental quality as a cost of doing business. And Mike King, director of the state’s Department of Natural Resources, this year advised companies to go above and beyond state requirements and reach out to communities. Such efforts won’t always be well-received, but they are essential to building community confidence.

Economics have also improved some practices. While newer state regulations require that companies pay to install more rigorous linings for waste-holding pits, some operators have gone another route, investing in pipelines to consolidate water-handling operations from several well pads at one facility. Encana estimates it has eliminated 120,000 truck trips per year in its Piceance Basin operations by collecting flowback fluids into pipelines that feed the company’s four water treatment plants— and then transport that water to be reused at new drilling sites. Fewer truck trips mean less potential for spills, as well as reduced emissions and dust from truck traffic.

Reusing water—and also reducing the amount needed—also means operators don’t need to purchase as much high-quality water from municipalities or other providers. Noble Energy, with a goal of reducing water needs to near-zero, has dedicated what are described as “significant resources” to figuring out how to achieve that goal. “It’s a good thing to do, but it’s also a prudent business practice,” says Ken Knox, senior advisor and water engineer for Noble. The greatest challenge, he says, is that water quality differs based on the geologic formation, “so we have to adapt to site-specific conditions.” What works in the Piceance Basin, for example, where the quality of produced water tends to be higher, doesn’t work in the Denver-Julesberg.

In Colorado, 51 percent of produced water and flowback is not recycled or treated and released, but injected into deep wells, some specifically designed for that purpose. Colorado has 325 such wells, but fluids are also injected into 575 non-producing oil wells in order to force lingering hydrocarbons through the formation and increase productivity in nearby wells.

Neshama Abraham, a steering committee member of Frack Free Colorado, points to many concerns about current disposal methods, as well as the plugging and abandonment of nonproducing wells. One of them involves the durability of concrete liners. “Who is available to see if there are cracks in that 50-year-old cement thousands of feet under the ground?” she asks.

Like oil and gas wells, disposal wells must be lined and cemented beneath the deepest potable aquifer, and the COGCC requires companies take steps to ensure the integrity of well casings. Cement bond logs, for example, are a required test to confirm the cement sealed properly. Pressure tests are used to monitor for potential breaches, and mechanical integrity tests are conducted every five years to look for holes in the casing of disposal wells. But Lepore concedes that the 40,000 plugged and abandoned wells in Colorado are problematic, in that procedures for plugging wells have changed over time. And only sketchy records of wells drilled prior to 1951 exist.

Still, drawing from her experience moderating the Center of the American West’s Fracking-SENSE series in early 2013, Limerick believes that air quality, especially because of the greenhouse potency of methane, may be a more deserving target for public anxieties regarding natural gas drilling than water contamination by hydraulic fracturing. But she does acknowledge risk. “Risk will never be entirely eliminated from the world of natural gas production…nor from the world of highway travel, cardiac surgery, food safety, recreational skiing, etc.,” she says.

She also cautions that the way scientists calculate probabilities of risk is very different from how “civilians” perceive them. The scientist has a non-personal assessment. The public views risks in an entirely personal way.

“The scientists are trying to speak in statistical terms about broad populations; the public is asking, ‘Am I in danger?’”

Print

Print