The next frontier of recycled water (and Beer)

Two sips into my Centurion Pilsner at a beer garden in Denver, I hiccupped. Hoppy beers do that to me. This beer was different. The water used for the brew came not from a river, a reservoir, or even a well. Instead, the purified water was sourced from a wastewater treatment plant located along the South Platte River. This simple fact didn’t bother me at all.

To be clear, I’m not a risk taker. Never skydived. Never paddled down Class V rapids. Never swallowed goldfish on a dare. But from what I’ve learned about purification processes for reclaimed water, drinking this limited-edition beer was eminently safe. The pilsner, blonde and translucent, like a Coors, looked and tasted like any number of beers made from water freshly obtained from creeks and rivers tumbling from Colorado’s mountain peaks. As for the strawberry-kiwi wheat beer ordered by my companion, I would have nothing of it. “That’s not beer,” I harrumphed, “that’s a fruit bowl. Undrinkable.”

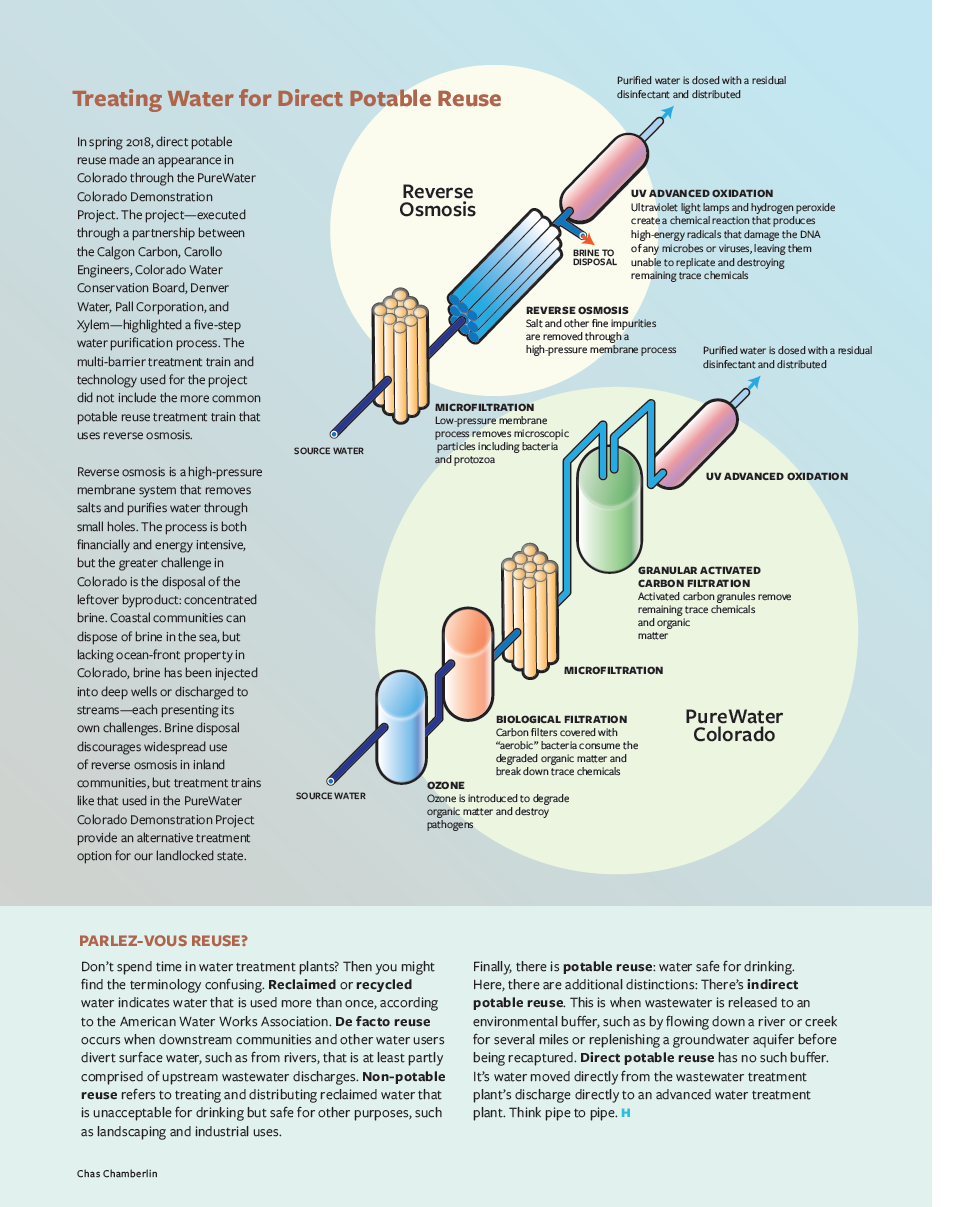

I was at Declaration Brewing Co., located in Denver’s Overland neighborhood. The brewery and also a winery, InVINtions, located in Greenwood Village, were part of a regional effort. Water for the one-time specialty beverages produced by both came from the PureWater Colorado Demonstration Project. In the demonstration that was conducted in spring of 2018, water providers, engineering companies and water reuse advocates collaborated to showcase direct potable reuse treatment technologies. The water was treated using five different processes until it met federal and state drinking water standards, suitable for human consumption.

Water always has been recycled. In her 2018 book “Replenish,” Sandra Postel points out that our morning coffee might contain molecules of deep fossil groundwater that the dinosaurs drank. Decades ago Colorado began deliberately recycling water, but only for landscaping purposes. More recent has been indirect potable reuse, where treated wastewater flows through an environmental buffer, such as a river, before being extracted for further treatment to make it suitable for drinking and other domestic uses.

Now, Colorado and several other water-stressed states are moving cautiously but deliberately toward direct potable reuse. “Widespread development of potable reuse will be an important facet of closing the future water supply-demand gap,” said the Colorado Water Plan of 2015.

Potable reuse most certainly won’t be a cure-all for Colorado’s water shortages. It’s just one potential tool in a kit, applicable for specialized settings. Engineers insist the technology exists to ensure water safe for human consumption. The larger question is whether the public will accept direct potable reuse, where that environmental buffer does not exist. The answer hinges, at least in part, on adoption of state standards governing treatment processes and monitoring protocols.

DEMAND BALANCED BY COST IN MONUMENT

The greatest interest in direct potable reuse comes from water providers along the urban Front Range corridor, particularly in towns between Denver and Colorado Springs still reliant upon wells. One of those places is Monument.

Monument lies 20 miles north of Colorado Springs near the crest of the Palmer Divide. With 8,000 water-drinking consumers, it is one of eight larger jurisdictions in northern El Paso County and a dozen or more small water providers that rely totally, or mostly, on water extracted from wells in the Denver Basin aquifers. Monument’s extraction of water from the Dawson and Arapahoe aquifers cannot be sustained. Groundwater levels have declined up to 20 feet a year as pumps have worked harder to supply a population expanding by 4 percent annually. Wells, which range from 30 to 1,750 feet in depth, can be drilled deeper, but only so far. Aquifers with high-quality water go only so deep.

“At some point, we either have to get a new water source or reuse our water,” says Nicholas Harris, the town’s water superintendent. “Is it a concern? Absolutely,” says Steve Sheffield, Monument’s assistant public works director. “We would be negligent in our jobs if we said that supplies of water were not a concern.”

Monument sees few alternatives. Water can be purchased from distant farms, but that requires pumping long distances uphill to the town’s 7,000-foot elevation. Such purchases also marginalize rural farming areas. Trying to get water from even more distant sources, such as the Colorado River and its tributaries, if theoretically possible, looks even more expensive and problematic. Plus, it reduces flows in those rivers.

Reuse appears to be the most viable option for Monument. The city has retained consultants, at a budgeted cost of $150,000, to study releases from the municipal wastewater treatment facility. Results expected by the end of 2018 will allow Monument to better understand exactly what treatments would be needed to purify water for potable reuse and what those treatments might cost.

What Monument will do with those results remains undecided. Indirect potable reuse is favored by Monument’s water officials. The treated wastewater could be pumped upstream and allowed to flow miles down Monument Creek before being recaptured and treated.

Direct potable reuse, absent the environmental buffer, would slash pumping costs but it might be a hard sell with water consumers, Harris says. He believes he could make a better case for direct potable reuse if state regulations were adopted. “We could say this is what is required and this is what we’re doing to meet those requirements.”

Adoption of state regulations would also give water providers certainty. No regulations or standards, state or federal, directly define or prohibit direct potable reuse in Colorado. Water providers could legally construct direct potable reuse systems today, then submit to state officials for approval. That, however, would leave them vulnerable to the risk of building something that might then need to be substantially modified in the future to comply with inevitable but as-yet-undefined regulations governing direct potable reuse.

Direct potable reuse is just one of several water supply options for Monument’s looming existential problem. “We’re looking to reduce our reliance on groundwater, whether that is [through] reuse, either indirect or direct potable reuse, or even a renewable surface supply,” says Harris.

Whatever Monument does, it hopes to have partners. “It boils down to cost,” says Harris. “There are economies of scale. So, if we can get two or three or four or more entities together, the overall cost increases, but it can be split among those entities, reducing everybody’s individual costs. Plus, all of us in northern El Paso County are in the same general boat.” Towns in that region need a sustainable water supply to supplement groundwater extractions. And reuse is an economic option.

REUSE IN COLORADO

What some people call de facto reuse has long occurred in Colorado and around the world. In summer, farmers in the lower South Platte River Valley depend on releases from the metro-area wastewater treatment plants. The largest plant, the Robert W. Hite Treatment Facility, processes wastewater from 1.8 million people. Located along the river near Interstate 270, the plant reclaims 130 million gallons of wastewater daily, or enough to fill nearly 200 Olympic-sized swimming pools. For nine months each year, treated discharges from the plant provide 85 percent of the flows of the South Platte River downstream from Denver.

Towns and cities also tap creeks and rivers that include diluted wastewater. Golden dips its straw into Clear Creek downstream from the treatment plants of Idaho Springs, Georgetown and Blackhawk. On the Western Slope, water for Avon and Beaver Creek comes from the Eagle River downstream from Vail’s treatment plant. Even in this headwaters state, most people live downstream from someone else.

Deliberate non-potable reuse in Colorado has occurred since the 1960s, when Aurora and Colorado Springs began using treated wastewater, also called reclaimed water, for landscape irrigation. Today, at least 27 jurisdictions deliberately treat wastewater to levels suitable for non-potable reuse. It is used for landscape irrigation and industrial purposes—with 500 different end uses altogether. Aspen intends to join the list when it begins using treated wastewater to irrigate a municipal golf course.

Denver Water has been looking to expand state-approved uses of treated wastewater. Working within its own borders, Denver delivers recycled water through a 70-mile network of purple pipes—used to identify the treated non-potable water—to more than 80 customers. They include 34 parks, 5 golf courses, and the city’s zoo. But reclaimed water for landscaping is needed only in warm-weather months. The supply is available year round.

Nicholas Harris, water superintendent for Monument, stands at Monument Lake. The town doesn’t own any surface water rights but uses the lake for augmentation and expects it to play a role in future reuse efforts. Photo By: Matthew Staver

This demand-supply mismatch triggered Denver to push for a Colorado Department of Public Health and Environment (CDPHE) review of Denver’s proposed expanded uses of reclaimed water for non-potable purposes. CDPHE’s review launched in 2016, with new regulations expected in fall 2018. In spring of 2018, the Colorado General Assembly passed legislation allowing deliberate use of reclaimed water for growing edible crops and industrial hemp as well as for flushing toilets and urinals, as Denver had originally proposed. Legislators said no to a fourth bill that would have allowed use of reclaimed water for marijuana cultivation. Cannabis growers feared they would be mandated to use reclaimed water and argued that ample research hadn’t yet been conducted on potential health impacts.

State Rep. Jeni Arndt, a Democrat from Fort Collins and a primary sponsor of three of the four bills that passed with bipartisan support, sees the new laws as steps forward in water conservation. “What I am trying to do is very intentionally build the tools to create the framework for a water-secure future,” she says.

PRAIRIE WATERS

Desperation has often driven efforts to recycle water. That was the case when the bone-dry drought of 2002 revealed Aurora’s vulnerability to water shortage. Getting new virgin water from the Western Slope might have taken decades. An easier and less costly solution was to drill 23 wells in the alluvial aquifer 50 to 100 feet from the South Platte River near Brighton. Treated wastewater released from the Hite plant north of downtown Denver flows 16 miles downstream in the river and through the adjoining alluvial aquifer. From the wells at Brighton, Aurora’s reusable water is pumped 34 miles and 1,100 vertical feet through a pipeline to the Peter Binney Water Purification Facility near E-470 and East Quincy Avenue. There it is subjected to several treatment processes then mixed with separately treated water imported from the mountains. This project, Prairie Waters, was completed in 2010.

Aurora has been using only 20 percent of the pipeline’s capacity, bringing raw water to the purification facility, but it expects to use more and to pump more from its wells as the population, now at 362,000, grows to 700,000 in coming decades. “We’re growing into it,” explains Aurora Water spokesman Greg Baker.

As with Monument, cost factors into Aurora’s water reuse. Deliveries from Prairie Waters cost 10 times as much as water imported from the Homestake Valley near Vail and other mountain sources, says Baker. Prairie Waters requires three pumping stations, and treatment needs further elevate costs. “There is no cheap way to reuse water,” says Baker, “but given the cost of water, [reuse] is becoming more cost effective. For everyone, it comes down to location, location, location. The water has to be relatively easy to recapture, and for some jurisdictions it’s just not practical.”

Prairie Waters illustrates how partnerships can lower individual costs and reduce locational problems. Half of the $638 million Prairie Waters cost was for the pipeline (with room in the right-of-way for a second pipeline). To pay down the enormous infrastructure cost, Aurora in 2008 began soliciting interest from water-strapped south suburban neighbors as well as Denver. The vision coalesced in 2014 when the Water Infrastructure and Supply Efficiency Partnership, or WISE, was approved. Ten South Metro communities began getting water deliveries through the WISE partnership in 2017.

Transbasin diversions by Denver and Aurora underpin the reuse component of WISE. The Blue River Decree, signed in 1955 but disputed long after, governs Denver Water’s imports from Dillon Reservoir, and requires Denver to maximize its transbasin imports before seeking additional water from the Western Slope. That imported water can be used and reused again and again to the legal definition of “extinction.” But much of the state’s treated water isn’t available for reuse. Under prior appropriation, after a first use, any unused water must be allowed to flow downstream to other users who then have a right to that water. Most, but not all, transbasin diversion water can be reused, as can other imported water including the consumptive use portion of transferred agricultural water and nonrenewable and nontributary groundwater. Water from the state’s largest transbasin diversion, the Colorado-Big Thompson Project, cannot be reused, except in the de facto reuse by those downstream. In addition, most of the water imported to metro Denver through the Moffat Tunnel cannot be reused.

Even so, there’s worry in the South Platte Valley that increased water reuse will mean less water for crops. “Irrigators and municipalities kind of clash when it comes to thinking that conservation is the way to fix the problems,” says Randy Ray, executive director of the Greeley-based Central Colorado Water Conservancy District. Joe Frank, general manager of the Lower South Platte Water Conservancy District in Sterling, also notes potential for diminished flows to canals and reservoirs. But the legal standing is unchallenged. “They have a right to use it,” Frank says of the legally allowed reuse.

Also unchallenged is the right of cities mining water from confined, non-renewable aquifers—including the Denver Basin underlying Monument, Parker, and Castle Rock—to recycle it. In Castle Rock, that matters entirely.

CASTLE ROCK

Castle Rock, a city of 62,000, was long reliant on wells drafting unsustainably on the same Denver Basin aquifers as Monument. It still is. However, since 2006, Castle Rock has been pivoting toward sustainable water supplies. Receiving WISE water starting in April 2018 was a giant step, boosting the city’s portfolio of renewable, non-groundwater supplies from 17 percent in 2017 to between 34 percent and 45 percent in 2018, depending upon how much utility customers use, how much water is available in the creek, and how much WISE water Castle Rock purchases.

Next comes a revamped treatment plant and indirect potable reuse system expected to be ready by 2020. The town’s treated wastewater will be allowed to flow five miles down East Plum Creek before being collected near Sedalia and pumped back to Castle Rock for further purification. Castle Rock uses a water treatment technology train that seems at least half as long as the mile-long coal trains that rumble through the town: seven steps before the final step of adding chloramines for disinfection. Cost of this reuse water will run $12,000 to $13,000 per acre-foot (in 2018 dollars), compared to the city’s best estimates of $30,000 per acre-foot or more for imported water.

Castle Rock’s new plant will have an option for pipe-to-pipe direct potable reuse including treatment processes that utility officials expect the state will require once it sets regulations to protect public health where direct potable reuse is implemented. Indirect potable reuse loses some water to the sands of East Plum Creek. Direct reuse would not incur stream losses. There’s little difference most years. “The only time direct reuse will produce significantly more water is when there is a drought that causes the creek to dry up,” says Mark Marlowe, the city’s director of utilities.

What’s holding Castle Rock back from going immediately to direct potable reuse? It’s a complicated chicken-and-egg situation, similar to that described by Monument’s superintendent. Marlowe wants more dialogue with customers first. And before doing that outreach, he wants explicit state regulations. Those regulations will implicitly testify to the adequacy of treatment, Marlowe believes.

Castle Rock Reservoir No. 1, near Sedalia, can hold up to 240 acre-feet of water. By 2020, Castle Rock Water plans to divert water off of Plum Creek—primarily comprised of treated effluent from the Plum Creek Water Reclamation Authority—pump it to this reservoir for storage, then pipe the water back to the purification facility when needed, for treatment and distribution to water users. Photo By: Matthew Staver

During the last decade, Marlowe says, Castle Rock’s customers indicated they’re “generally comfortable with indirect reuse, which includes the environmental interface of East Plum Creek or Rueter-Hess,” he says, the latter a reference to the reservoir between Parker and Castle Rock. “We have not invested significant outreach in direct potable reuse at this point, as we will likely wait for the state to be further along in regulations before we take time to do that.”

PERCEPTION AND PUREWATER

Centurion, the beer named to reflect Denver Water’s 2018 centennial anniversary, was part of the effort to build trust among Coloradans in recycled water. So was the PureWater Colorado Demonstration Project. The project at Denver Water’s recycling plant showcased methods used to deliver purified direct potable reuse water that in its quality and safety is just as good, if not better, than bottled water from a grocery store shelf.

Hundreds of people were shown the tangle of pipes and tanks, among them state legislators, water officials and journalists, including me. “I think I can detect the undertones of the Blue River,” I sniffed to my companion as I swirled a sample of the water in a plastic cup.

Five treatments were used, but salt remained in the water. All water has some salt. The more water is recycled, the higher the salt content and total dissolved solids, or TDS. TDS is the more technical term for salts, metals, minerals and other matter dissolved in water. The level of salt remaining in water after purification is not a health problem, but it poses a giant problem of perception. It changes the taste, what some call drinkability.

“We will have to pay as much attention to the taste, the drinkability of it, as to the public health,” says Allegra da Silva, of Brown & Caldwell, an engineering firm in Lakewood. She is also president of WateReuse Colorado, an advocacy group of water professionals. “The things that can actually harm you, you can’t taste. The things you can taste in water are not harmful. In potable reuse, we have to provide both purity and drinkability. We can do that with the right treatment,” says da Silva.

The public may not notice this change in taste, she says, if the increase in salt is gradual. And if jurisdictions blend higher-salt recycled water with other supplies, such as from wells or imports from the mountains, taste may not be an issue. After all, the International Space Station manages to pull this off without having imports from mountain streams. But taste matters to the public. “If it doesn’t taste ‘right,’ they may perceive that it’s not healthy,” says da Silva.

REUSE SAFETY, TREATMENT TECH AND HEALTH

Perception along with technology and many other things have changed since 1998, when a National Research Council report said reclaimed water should be a “solution of last resort” for drinking water. By 2012, the same group said “use of treated wastewater … could significantly increase the nation’s total available water resources.”

What changed? A 2018 report by the U.S. Environmental Protection Agency and others called “Mainstreaming Potable Water Reuse in the United States” credited the “development of a community of practitioners who understand the ingredients necessary to successfully implement potable reuse projects along with greater acceptance among the public and decision makers.”

EPA looks over the shoulder of state regulators to ensure healthy drinking water. It regulates contamination by both occurrence and magnitude. In other words, how often does something show up and at what strength? Analytical techniques have become so effective that chemicals can be detected at concentrations that pose no public health threat. Multiple, redundant and diverse treatment barriers remove the unseen and possibly dangerous impurities to levels specified by the EPA under the federal Safe Drinking Water Act and the Clean Water Act.

“One treatment technology alone is probably not going to get us to where we need to go to meet water quality standards,” says Austa Parker, a water reuse technologist with Broomfield-based Carollo Engineers. “But when you couple them together and target various chemicals and pathogens, you create treatment trains that can cover the whole spectrum.”

Chemicals must be present at a certain level before they have a health impact, says Parker, but a more traditional concern has been pathogens. “That is our No. 1 concern in any sort of water treatment or wastewater treatment process. [Pathogens] represent a threat of infection, and we want to be completely protective of public health,” says Parker. “So we monitor. We monitor for indicators of all types of viruses and protozoa and giardia—any kind of human waste or animal waste. We want to be protective. We have multiple barriers in place in direct potable reuse for that reason.”

But monitoring for indicators is different than continuously monitoring for pathogens and the absence of continuous monitors capable of detecting pathogenic organisms could be an issue for direct potable reuse. “We are able to test for almost any known contaminant, but for some, the turnaround time can be long and the tests can be expensive,” says Caroline E. Scruggs, an associate professor at the University of New Mexico and co-author of a 2017 paper published in the Journal of Water Resources Planning Management. She believes more monitoring techniques are needed. “The monitoring is still evolving and will continue to get better,” Scruggs says.

CREATING REGULATIONS

While engineers and reuse technologists work to remove contaminants and monitor for safety, the Colorado Department of Public Health and Environment has and will continue to be the fulcrum for water reuse as it is responsible for drawing up regulations. It has started doing so on two tracks. One is the rulemaking being conducted by the agency’s Water Quality Control Commission to express the intent of the laws adopted by the General Assembly in 2018 to expand the allowed non-potable uses of reuse water to toilets and urinals, edible crops, and industrial hemp.

As for direct potable reuse, CDPHE has been discussing it with water providers and environmental advocates since 2016. Absent a specific proposal to deploy direct potable reuse, the state has moved at what officials describe as a “measured” and “thoughtful” pace. The agency has worked with and supported the efforts of WateReuse Colorado to define what should be addressed by state regulations.

In the first phase of this collaborative work with WateReuse Colorado, a workgroup of stakeholders in Colorado and national experts outlined how to go about this process. The second phase, which began in summer 2018 and is expected to take a year, involves more substantive matters, including treatment technologies and monitoring requirements. This is all in advance of a formal rulemaking process that would yield regulations governing direct potable reuse.

Ron Falco, CDPHE’s Safe Drinking Water Program manager, says the state initially wrestled with whether to be prescriptive in direct potable reuse regulations or flexible. California has been moving toward prescriptive “thou-shalt” regulations. Texas has opted for a more site-specific and flexible approach. “Through our discussions we realized that there are benefits to both approaches,” Falco says. “A more prescriptive approach may be able to be implemented quickly, but the site-specific approach may be best for utilities that are not in a big hurry.” This, he says, shows the benefit of moving forward at the measured pace, and Colorado now hopes to incorporate aspects of both approaches into its regulatory framework. No funding has yet been secured for this rulemaking process. If funding is available soon, a formal rulemaking process could begin in 2020. Again, while the absence of regulation doesn’t prohibit direct potable reuse in Colorado, utilities want the certainty those regulations would provide.

Still unclear is just how important water reuse, whether for human consumption or other purposes, will be in Colorado. The state water plan identified it as an important tool in meeting future water demands. State water officials, however, concede that they really don’t know how much water is legally available for reuse, let alone how much water is available after practical considerations such as actual river flows and cost constraints are considered.

But Colorado is essentially out of new water to develop, and people keep moving here—especially to water-short places. Wells in Castle Rock, Monument and other communities that draw on the Denver Basin aquifers continue to be less productive. If direct potable reuse is not the answer to every problem, it looks to be a tool in some places. “Water should be judged not by its history, but by its quality,” said Dr. Lucas Van Vuuren, a pioneer in water reclamation in South Africa. Come to think of it, isn’t that how we judge our beers?

Print

Print